was established in 2018, and is a professional warehouse automation technology company in China. Our company has a group of knowledgeable and experienced employees, who excel at both project design and implementation. We focus primarily on the research and development, design, and manufacturing of core equipment for the dense storage system, the four-way shuttle car robot device, as well as the system integration of fully automated longitudinal and transverse vehicles.

-

Industry experience

We started with technology, have 12 years of experience in R&D and manufacturing of two-way shuttle vehicles, and have accumulated hundreds of excellent cases. At the same time, it has created 6 years of experience in research and development and project implementation of four-way shuttle vehicles and intensive warehouse system products. We focus on the four-way intelligent intensive library, and are the first batch of companies in China to research the four-way intensive system

-

Product advantages

1.4D Intelligent Intensive Storage System is the upgraded replacement of traditional shuttle racking, ASRS, drive-in racking, gravity flow racking, mobile racking and push back racking.

2. Possess patents, master core technologies and core products;

3. Standardized system, accurate and fast, easy to implement; ranks in the industry leader;

4. The self-designed main track and sub-track structure are better stressed, save space and lower cost;

5. The core equipment four-way vehicle realizes parameterized debugging mode, intelligent program, mechanical jacking, light body, more flexible operation and higher safety. -

After-sale mechanism

1. Respond within 2 hours after receiving a user failure call;

2. Full-time engineers accept;

3. Digital twin, enabling the company to directly monitor the site;

4. On-site debugging and regular inspection;

5. Remote technical consultation and guidance;

6. Free replacement of spare parts during the warranty period;

7. Possess a perfect transnational after-sales service system. -

Order without fail

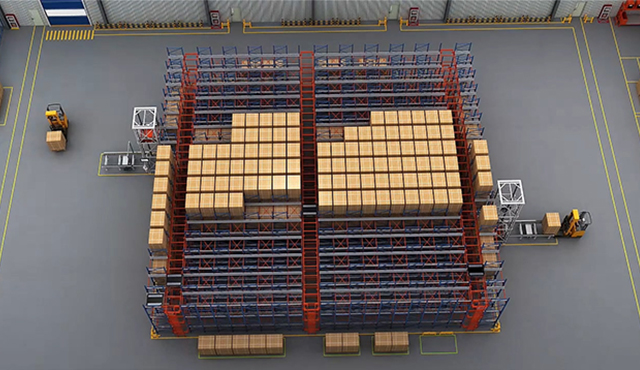

The four-way shuttle is mainly used for the automatic handling and transportation of pallet goods in the warehouse, automatic storage and retrieval, automatic lane change and layer change, and shuttles vertically and horizontally on the shelf track. It has flexibility and accuracy. It is a combination of automatic handling and unmanned guidance. Intelligent control and other multi-functional intelligent shuttle vehicle handling equipment. The working environment is safe, labor costs are saved, and storage efficiency is greatly improved.

Our Product

The core equipment four way pallet shuttle realizes parameterized debugging mode, intelligent program, mechanical jacking, light body, more flexible operation and higher safety.

view all product

News Center

-

Mexico Four-way Intensive Warehouse Proje...

17/10/24

This project is a cooperation project between Nanjing 4D Intelligent Storage Equipment Co., Ltd and a trading company from Shanghai, and the end customer is a Mexican company. Our company is ... -

The Development History of Automated Storage

19/09/24

It’s a inevitable rule that things will constantly develop, update and change. The great man warned us that the development of any thing has its own unique rules and processes, and it takes a... -

How to Choose an Appropriate Four-way Int...

13/09/24

The market is changing fast, and science and technology are also developing rapidly. In this period of rapid development, our automated warehousing tec...

Leave Your Message

Please enter the verification code