4D Intelligent Smart Factory Solution

Use digital twin technology to help visualize smart factory operation management, integrate industrial data, Internet of Things, artificial intelligence and other technologies, integrate data resources of the factory's existing information system, and restore the real factory through digital twin technology

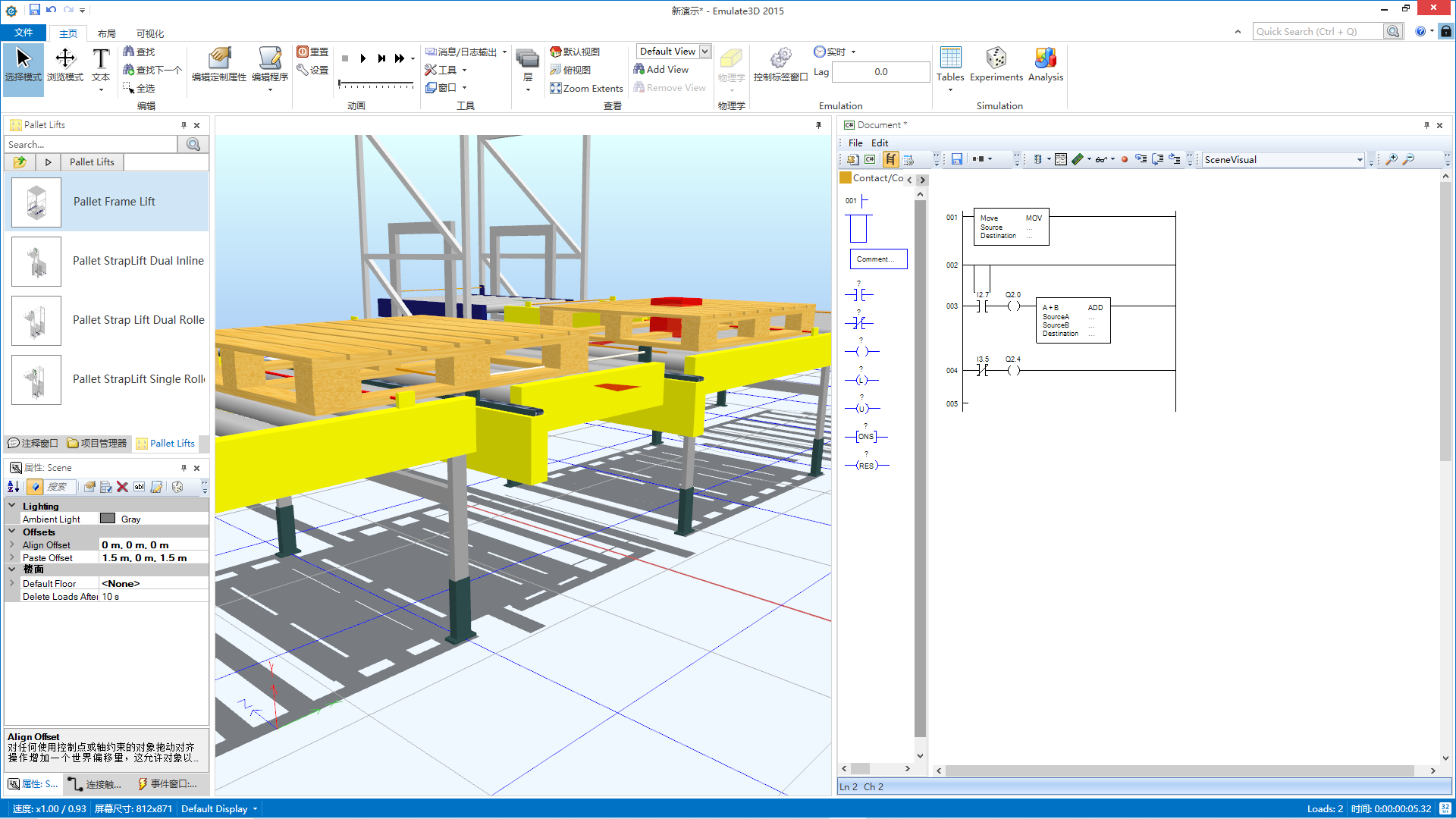

1. Simulation debugging

The 4D shuttle intelligent digital twin system can build a 3D simulation demonstration based on its real application scenarios for customers. With the help of 3D modeling software modeling, the software platform builds logistics scenarios, which can restore the image of the equipment and operation process in factory, and combine it with the digital process. A virtuous cycle of static design—dynamic process, verification—dynamic process display—design drawing is formed, which greatly improves the efficiency and accuracy of design, and provides decision support for management, analysis, and optimization.

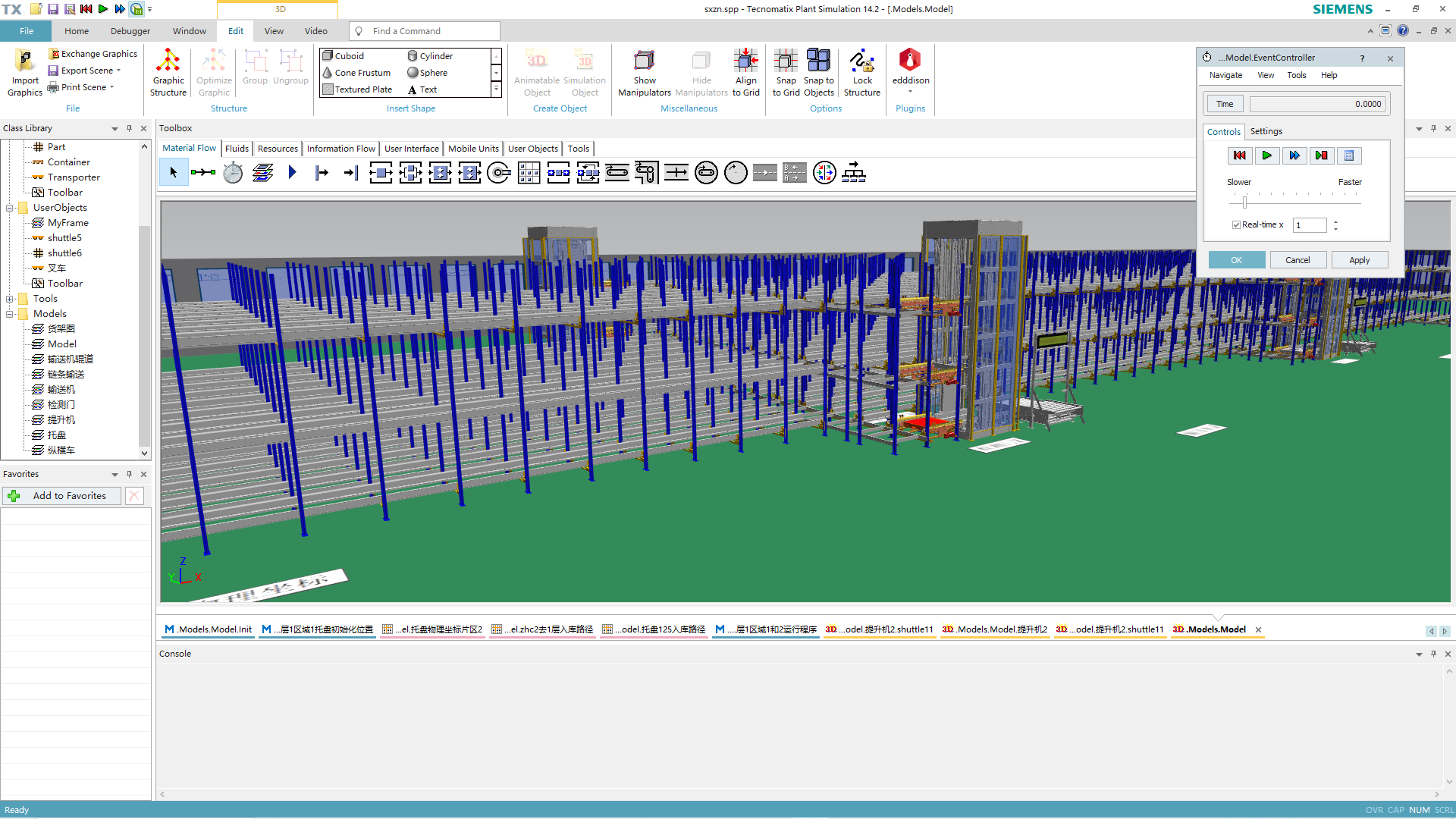

2. Operation and maintenance monitoring

(1) Based on the standard communication interface, the monitoring data scattered on each device is connected and integrated to form a unified production monitoring platform to realize the virtual and real interaction between the factory and the digital factory. The 3D scene monitors the operating status of the equipment, and intelligently displays the early warning according to the early warning equipment and early warning time.

(2) Provide a powerful operation and maintenance management system, visualize production operation and inspection, manage the entire life cycle of equipment, monitor status and performance, analyze production and operation data, and provide analysis reports to customers for relevant maintenance reminders and other functions , which can quickly analyze abnormalities, and provide reliable pre-judgment analysis to ensure safe, stable, long-term, full, and optimal operation of the factory.

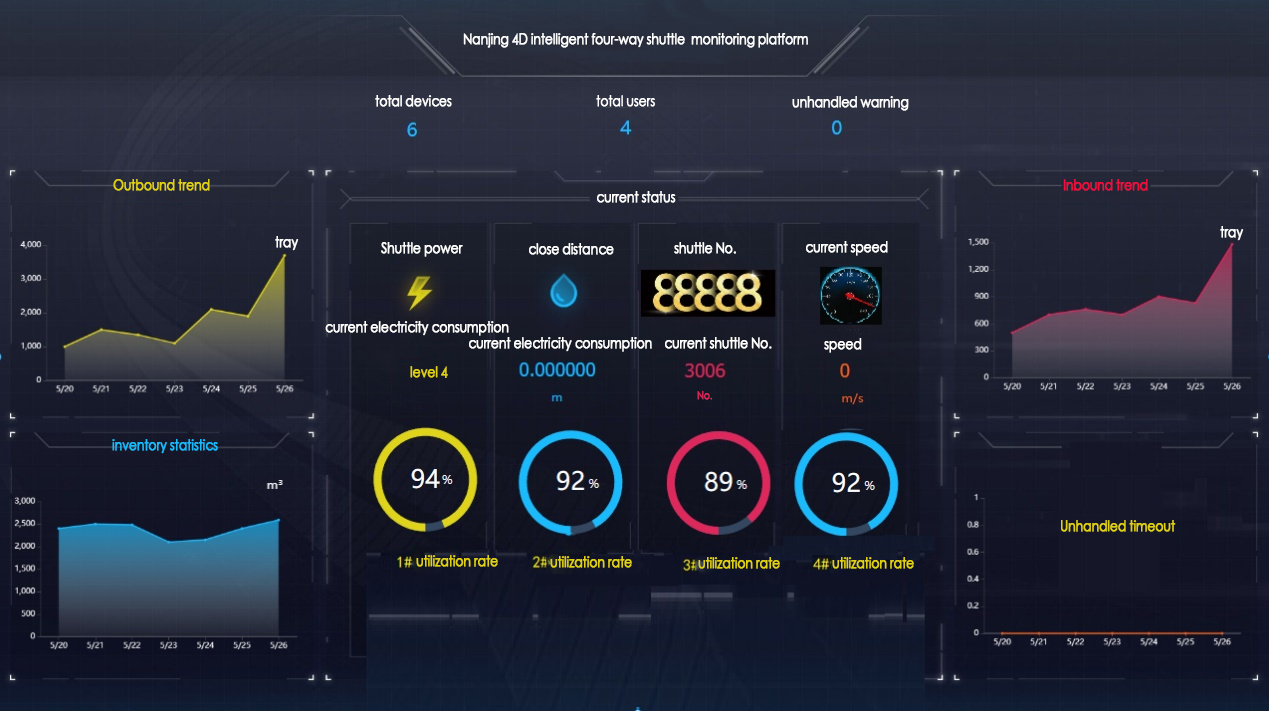

3.Smart Board

Production big data visualization through data collection, on the one hand, it can directly display the key information of warehouse operation in real time, and on the other hand, it can analyze and display the meaning behind the data in a timely and effective manner. Managers can clearly understand the current operating efficiency of the warehouse area, Inventory and other key information to facilitate the adjustment of management strategies;