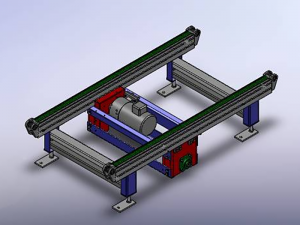

Palletizer

Features

● The structure is simple and only a few parts are needed. The result is low part failure rates, reliable performance, simple maintenance and repair, and fewer parts to keep in stock.

● The space occupation is small. It is convenient for the assembly line layout in the user's factory building, and at the same time, a larger storage space can be reserved. The stacking robot can be installed in a small space and can play its role.

● Strong applicability. If the customer's product size, volume, shape, and external dimensions of the tray have any changes, just fine-tune it on the screen to ensure the normal production of the customer. While the mechanical stacking method is difficult to change.

● Low energy consumption. Usually the power of the mechanical palletizer is about 26KW, while the power of the palletizing robot is about 5KW. Greatly reduce the customer's operating costs.

● All controls can be operated on the control cabinet screen, easy to operate.

● Just locate the grabbing point and placement point, and the teaching and explanation method is easy to understand.

Specifications

| Product number | 4D-1023 |

| Battery capacity | 5.5KVA |

| Degrees of freedom | Standard four-axis |

| Valid loading capacity | 130KG |

| Maximum activity radius | 2550mm |

| Repeatability | ±1mm |

| Range of motion | S axis :330°

Z axis:2400mm X axis:1600mm T axis:330° |

| Body weight | 780KG |

| Environmental conditions | Temp. 0-45℃, Temp. 20-80% (no condensation), vibration below 4.9m/s² |

Application scenario

Palletizers are widely used in logistics packaging, storage and handling in food and beverage, chemical, electronics, pharmaceutical and other industries.