1. Training in Meeting Room

This month, Nanjing 4D Intelligent Storage Equipment Co., Ltd. carried out a comprehensive renovation and upgrade of its workshop according to the “6S” policy, aiming to improve the company's operating efficiency and create an excellent corporate image.

Before the plan started, the responsible person introduced the “6S” Lean Production Management plan to us in the meeting room, and explained the expected effects of the plan, and the specific rectification and upgrading steps in detail.

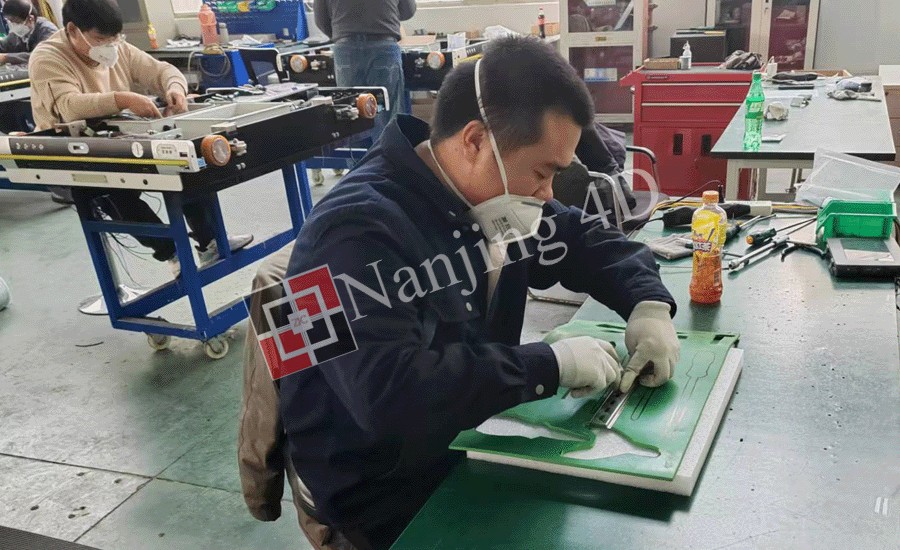

2. The Renovation Process

During the renovation process, employees actively participated in the plan, worked hard to rectify the messy areas of the workshop, plan each partition of the workshop, and store and organize items in modules.

●Warehouse area renovation: sort out and remove wasted paper boxes, and arrange various materials neatly according to different categories

●Mechanical assembly area Renovation: arrange the parts in partitions, fix labels at corresponding positions, sort the parts in categories and put them in corresponding positions.

●Electrical area Renovation: organize electrical assembly tools, keep them ready to use at any time, saving time and improving efficiency

●Commissioning area Renovation: tidy up the area, discard useless items, and plan the placement of items

3. Acceptance

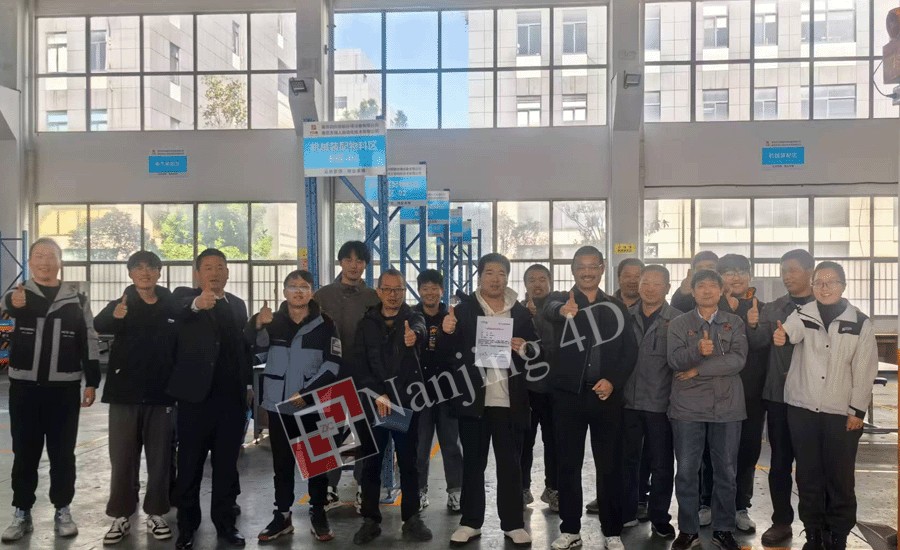

The workshop renovation and upgrade plan took about a week. With the efforts of all employees and leaders, the plan finally came to the final acceptance stage.

During the acceptance process, the leaders strictly followed the “6S” requirements, carefully inspected and evaluated the different modules of the workshop, and finally successfully completed the acceptance work and presented awards to outstanding employees.

4. Comparison of workshop before and after rectification and upgrading

The workshop renovation and upgrade plan was successfully completed. The workshop working environment, item placement and equipment placement etc. were better planned. The contrast before and after the renovation and upgrade is clear.

In short, this workshop upgrade plan was completed with the joint participation of all employees and leaders. Its successful completion is the result of the joint efforts of all employees! In the future, Nanjing 4D Intelligent Storage Equipment Co., Ltd. will continue to implement this renovation plan and keep a good workshop management system!

Post time: Dec-12-2024