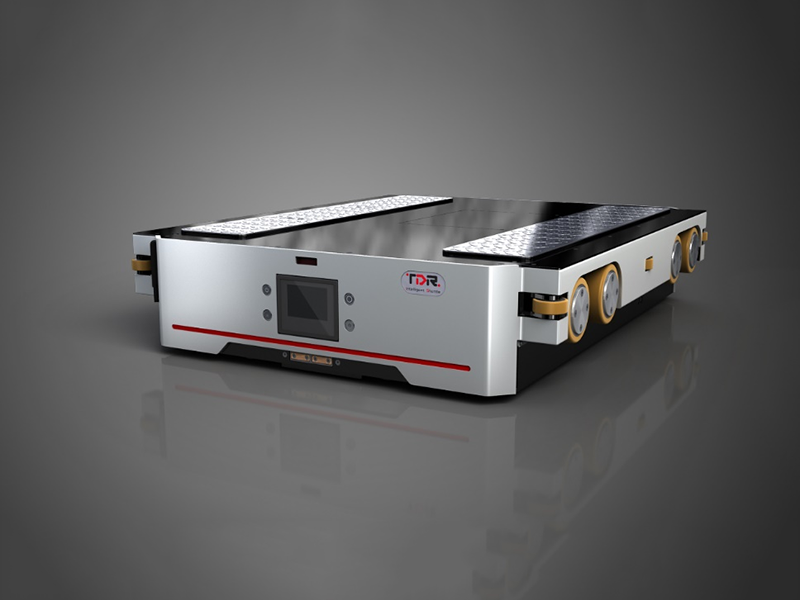

4D shuttle systems standard type

The vertical and horizontal car is composed of two sets of drive systems and two sets of jacking systems. The two sets of drive systems are responsible for the walking of the primary and secondary aisles; one of the two sets of jacking systems is responsible for the lifting of goods, and the other is responsible for driving the primary and secondary aisles. Switching; both the main channel and the secondary channel adopt DC brushless servo operation speed regulation, the speed regulation curve is smooth, and the operation stability is good. Both the main jacking and secondary jacking devices use brushless DC motors, which rely on rack and pinion mechanisms to rise and fall.

The vertical and horizontal car has five modes: remote control, manual, semi-automatic, local automatic and online automatic.

It comes with multiple security protections and security warnings, regional security alarms, operational security alarms and interactive security alarms.

standard business

Receipt assembly and storage out of warehouse

Relocation and inventory charging change layer

Technical parameters

| project | Basic data | Remark | |

| model | SX-ZHC-B-1210-2T | ||

| Applicable tray | Width: 1200mm Depth: 1000mm | ||

| Maximum load | Max 1500kg | ||

| height/weight | Body height: 150mm, Shuttle weight: 350KG | ||

| walk main X direction | speed | No-load maximum: 2.0m/s,Full load highest:1.0m/s | |

| walking acceleration | ≤1.0m/S2 | ||

| motor | Brushless Servo Motor 48VDC 1000W | Brushless Servo | |

| server Driver | Brushless Servo Driver | Domestic servo | |

| Walk in Y direction | speed | No-load maximum: 1.0m/s, full load maximum: 0.8m/s | |

| walking acceleration | ≤0.6m/S2 | ||

| motor | Brushless Servo Motor 48VDC 1000W | Brushless Servo | |

| server Driver | Brushless Servo Driver | Domestic servo | |

| cargo jacking | Jacking height | 30mm | |

| motor | Brushless Motor 48VDC 750W | Domestic servo | |

| main jacking | Jacking height | 35mm | |

| motor | Brushless Motor 48VDC 750W | Domestic servo | |

| Main channel/positioning method | Walking positioning: barcode positioning/laser positioning | Germany P+F/SICK | |

| Secondary channel/positioning method | Walking positioning: photoelectric + encoder | Germany P+F/SICK | |

| Tray positioning: laser + photoelectric | Germany P+F/SICK | ||

| Control System | S7-1200 PLC Programmable Controller | Germany SIEMENS | |

| remote control | Working frequency 433MHZ, communication distance at least 100 meters | Import customized | |

| Power supply | lithium battery | Domestic high quality | |

| Battery parameters | 48V, 30AH, use time ≥ 6h, charging time 3h, rechargeable times: 1000 times | maintenance free | |

| speed control method | Servo control, low speed constant torque | ||

| Crossbar control method | WCS scheduling, touch computer control, remote control control | ||

| operating noise level | ≤60db | ||

| Painting requirements | Rack combination (black), top cover red, front and rear aluminum white | ||

| ambient temperature | Temperature: 0℃~50℃Humidity: 5% ~ 95% (no condensation) | ||